- 1/8"NB TO 30"NB IN

- SS 317/317L

- 0.35mm to 6.35mm OD in thickness ranging from 0.1mm to 1.2mm.

- Seamless / ERW / Welded / Fabricated / LSAW Tubes

- Single Random, Double Random & Cut Length.

- Low thermal expansion and higher heat conductivity than austenitic steels

- Good workability and weldability.

- High energy absorption

- Excellent finish

- Durable

- High strength

- High resistance to pitting, crevice corrosion resistance

- High resistance to stress corrosion cracking, corrosion fatigue and erosion

- Good sulfide stress corrosion resistance

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 317L | 1.4438 | S31703 | SUS 317L | – | – | – | X2CrNiMo18-15-4 |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

| 317L | min. | – | – | – | – | – | 18.0 | 3.0-4.0 | 11.0 | – |

| max. | 0.08 | 2.0 | 1.0 | 0.040 | 0.030 | 20.0 | 15.0 | – | ||

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 317L | 515 | 205 | 35 | 75 | 205 |

Additional Information

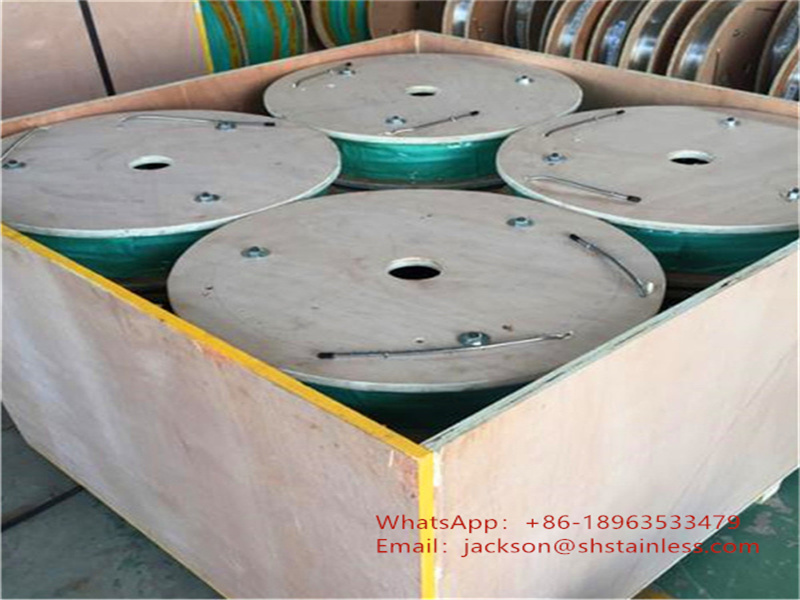

| Packaging Details | Stainless Steel 317/317L Coil Tubes are surface wash and clean to remove all impurities and stock in the warehouse. Then it is wrapped in thin plastic and also it ends are protected by plastic caps to avoid any damage in transit. Stainless Steel 317/317L Coil Tubes is bundled in bubble wrap followed by assorting them in colored plastic bundles. An outer rope is tied to protect the tubing and they are packed in wooden box or container. M P Jain Provide Stainless Steel 317/317L Coil Tubes with all necessary documents such as commercial invoice/ packing list/ Test Reports/ HS Code/ Country of Origin attested by the chamber of commerce/ Fumigation Certificate/ Warranty Letter/ and Base Material Certificates. Every lot is supplied with a material test certificate as per EN 10204 NACE 3.1 standards indicating the chemical and mechanical properties of the Instrumentation Tubes. We also confirm the guarantee of the Stainless Steel 317/317L Coil Tubes supplied as per Purchase order specifications and attest the same in the Material Test Certificate. We also welcome any third party inspection from an agency nominated by the customer to comply with NACE 3.2 Certification if required by the customer at an extra cost. |