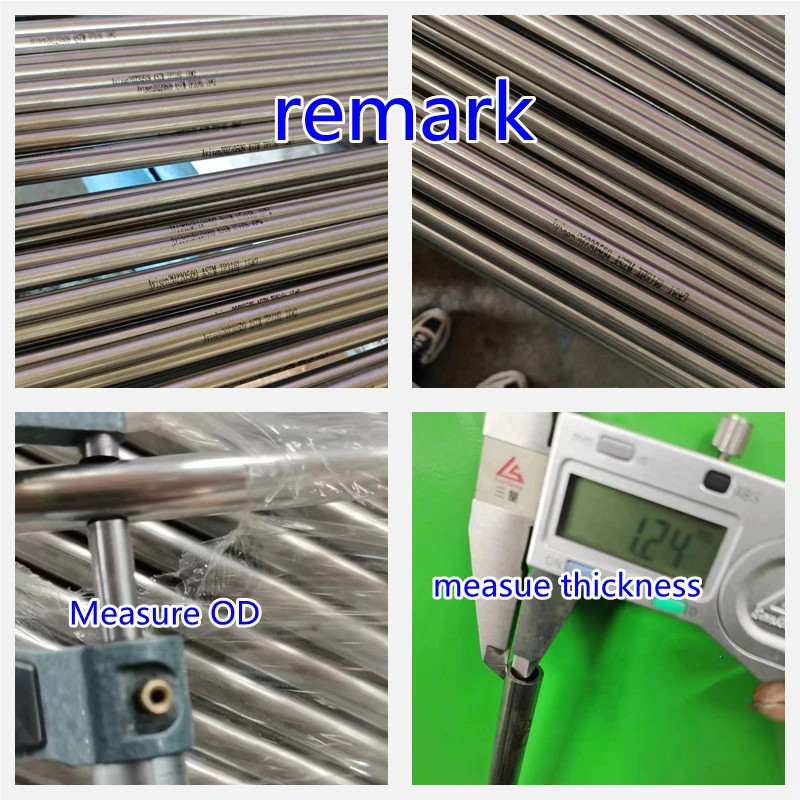

- Diameters:3.175-50.8mm(1/8"-2inc)

- W. T.: 0.3 - 3mm

- Grades: 304 316304 304L 316 316L 310S 2205 2507 625 825 etc.

- Standard: GB/ISO/EN/ASTM/JIS, etc.

- Tolerance: OD: +/-0.01mm; Thickness: +/-0.01%.

- Surface: Bright or anneald and soft

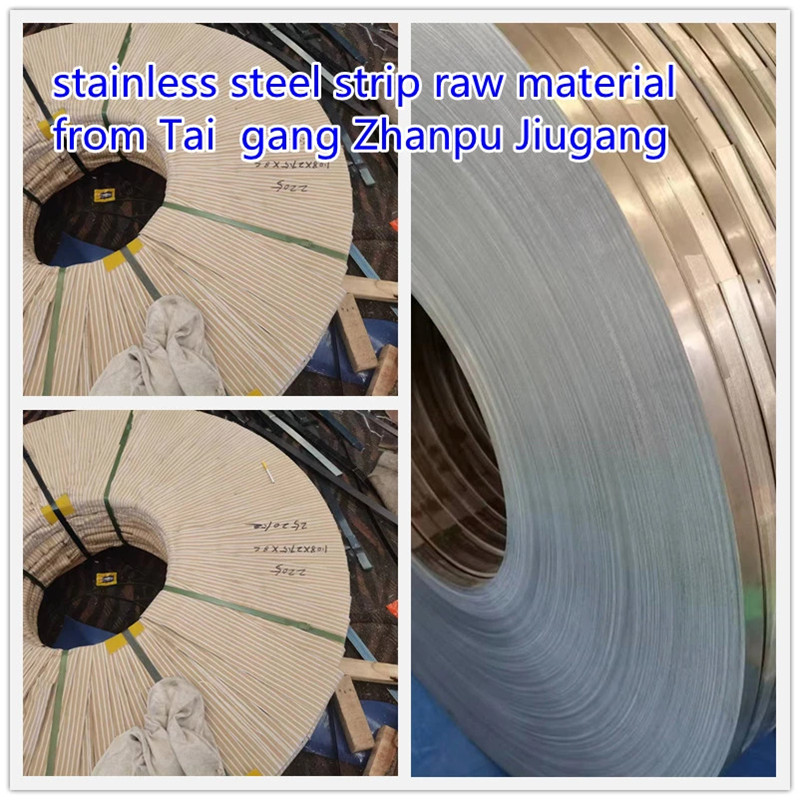

- Material: 304, 304L, 316L, 321, 301, 201, 202, 409, 430, 410,alloy 625 825 2205 2507 etc.

- Packing: LCL wooden case poly bay,FCL steel self or poly bay

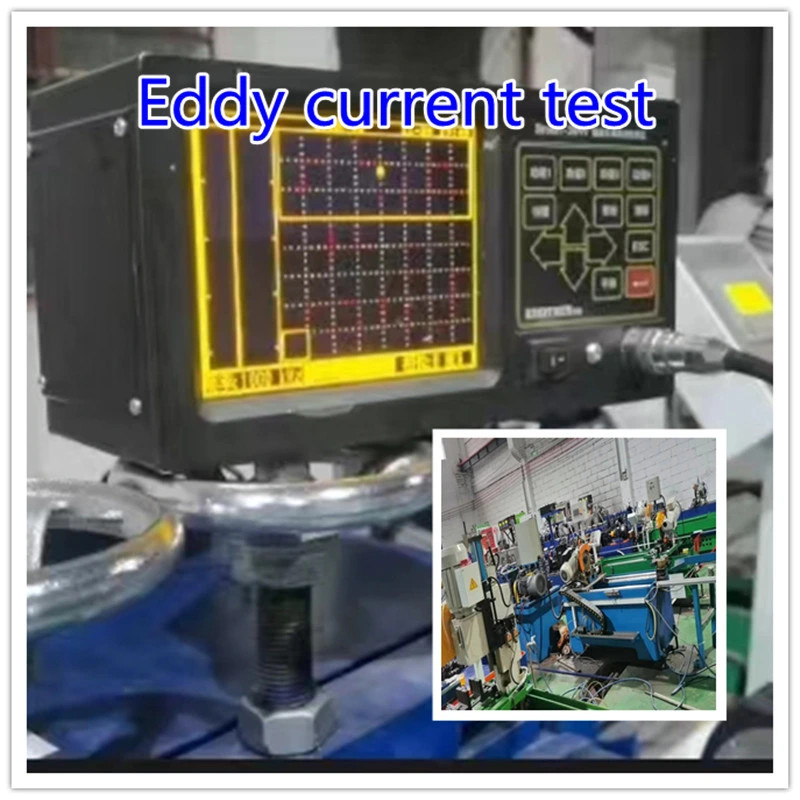

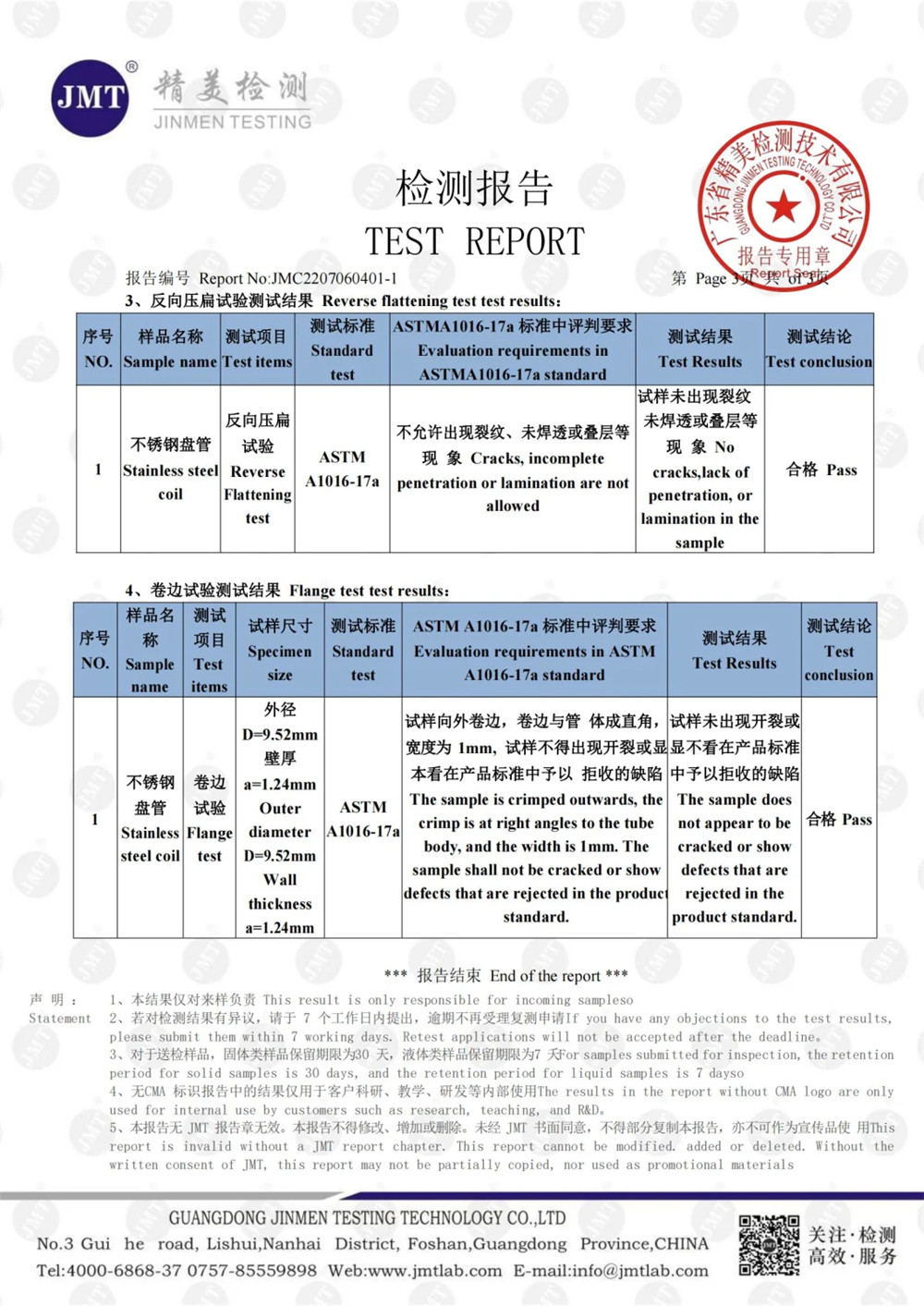

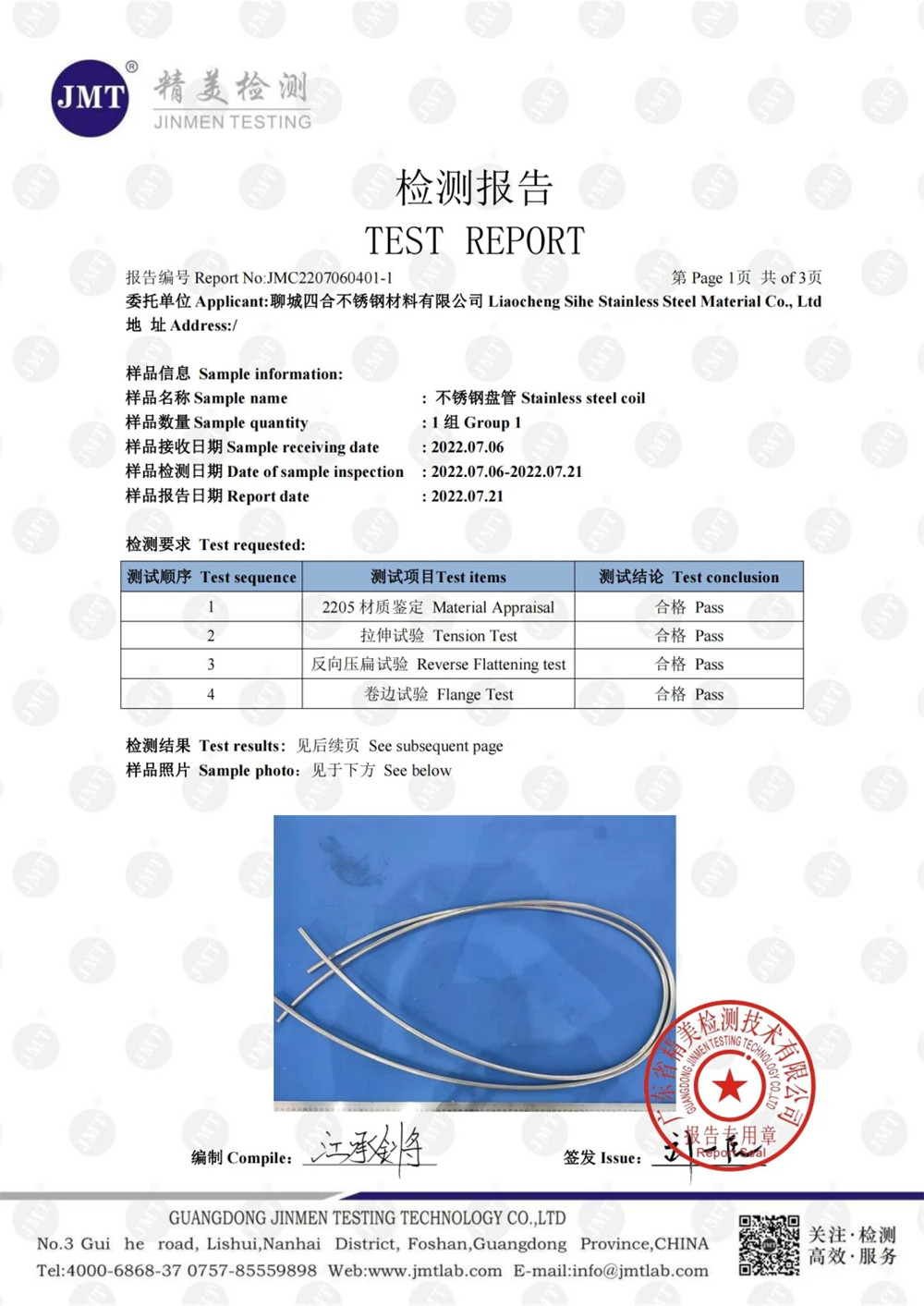

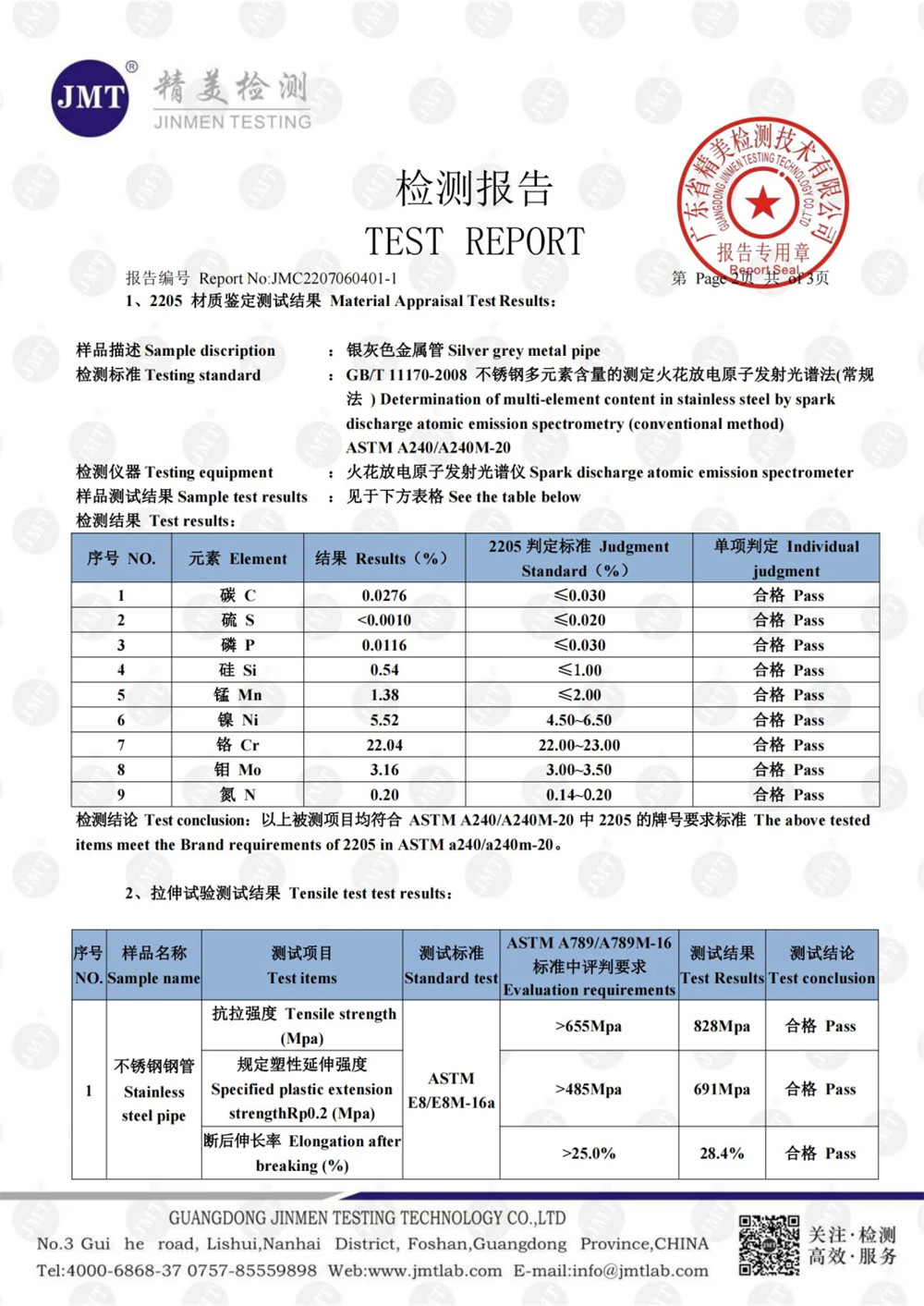

- Test :Yield strength, tensile strength, hydrapress measurement

- Guarantee: The third party (for example :SGS TV ) cetification ect.

- Application: Decoration, furniture, railing making, paper making, automobile, food processing, medical.

- Advantage: we are a manufacturer. with good quanlity and reasonable price. we can meet you all the needed. we are profession

| Product Name | stainless steel coiled pipe/tube |

| Material | 201,202,304.304L.316.316L.317.317l.321,310s.410.420.430.904l or custom for you |

| Thickness | 0.1-2.0mm |

| Diameter | 0.3-25mm |

| Length | 200-1500m per coil or Depending on your requirement |

| Standard | ASTM A269-2002.JIS G4305/ GB/T 12770-2002GB/T12771-2002 |

| Surface | Bright annealing,180G, 240G, 320G Satin / Hairline,400G, 600G ,Mirror finish |

| Package | weaving bag, non-woven fabric, seaworthy bundle,wooden case or according customer's requests |

| Usage | construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical,industry, boiler heat exchanger, machinery and hardware fields ,etc. |

| Material | ASTM A269 Chemical Composition % Max | ||||||||||

| C | Mn | P | S | Si | Cr | Ni | Mo | N B | Nb | Ti | |

| TP304 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 18.0-20.0 | 8.0-11.0 | ^ | ^ | ^ | ^ |

| TP304L | 0.035 | 2.00 | 0.045 | 0.030 | 1.00 | 18.0-20.0 | 8.0-12.0 | ^ | ^ | ^ | ^ |

| TP316 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 | ^ | ^ | ^ |

| TP316L | 0.035 D | 2.00 | 0.045 | 0.030 | 1.00 | 16.0-18.0 | 10.0-15.0 | 2.00-3.00 | ^ | ^ | ^ |

| TP321 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 17.0-19.0 | 9.0-12.0 | ^ | ^ | ^ | 5C -0.70 |

| TP347 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 17.0-19.0 | 9.0-12.0 | 10C -1.10 | ^ | ||

| Material | Heat treatment | Temperure F (C) Min. | Hardness | |

| Brinell | Rockwell | |||

| TP304 | Solution | 1900 (1040) | 192HBW/200HV | 90HRB |

| TP304L | Solution | 1900 (1040) | 192HBW/200HV | 90HRB |

| TP316 | Solution | 1900(1040) | 192HBW/200HV | 90HRB |

| TP316L | Solution | 1900(1040) | 192HBW/200HV | 90HRB |

| TP321 | Solution | 1900(1040) F | 192HBW/200HV | 90HRB |

| TP347 | Solution | 1900(1040) | 192HBW/200HV | 90HRB |

| OD, inch | OD Tolerance inch(mm) | WT Tolerance % | Length Tolernace inch(mm) | |

| + | - | |||

| ≤ 1 / 2 | ± 0.005 ( 0.13 ) | ± 15 | 1 / 8 ( 3.2 ) | 0 |

| > 1 / 2 ~1 1 / 2 | ± 0.005(0.13) | ± 10 | 1 / 8 (3.2) | 0 |

| > 1 1 / 2 ~< 3 1 / 2 | ± 0.010(0.25) | ± 10 | 3 / 16 (4.8) | 0 |

| > 3 1 / 2 ~< 5 1 / 2 | ± 0.015(0.38) | ± 10 | 3 / 16 (4.8) | 0 |

| > 5 1 / 2 ~< 8 | ± 0.030(0.76) | ± 10 | 3 / 16 (4.8) | 0 |

| 8~< 12 | ± 0.040(1.01) | ± 10 | 3 / 16 (4.8) | 0 |

| 12~< 14 | ± 0.050(1.26) | ± 10 | 3 / 16 (4.8) | 0 |

1. Q: Do you have the Stainless Steel coil tubing in stock ? A: We have Stainless Steel coil tubing,also can produce according to your order needed: 2. Q: What's the delivery time ? A: Within ten days after payment. 3. Q: Can I get some samples free ? A: Free sample can be provided if you require to check the quality. 4. Q: How do you make our business long-term and good relationship ? A: We keep good quality and competitive price to ensure our customers benefit . 5. Are you manufacturer ? A: YES (We have 6 Production lines )

1. Q: Do you have the Stainless Steel coil tubing in stock ? A: We have Stainless Steel coil tubing,also can produce according to your order needed: 2. Q: What's the delivery time ? A: Within ten days after payment. 3. Q: Can I get some samples free ? A: Free sample can be provided if you require to check the quality. 4. Q: How do you make our business long-term and good relationship ? A: We keep good quality and competitive price to ensure our customers benefit . 5. Are you manufacturer ? A: YES (We have 6 Production lines )