DIN 1.4438 EFW Tube Available According To International Standards And Specifications

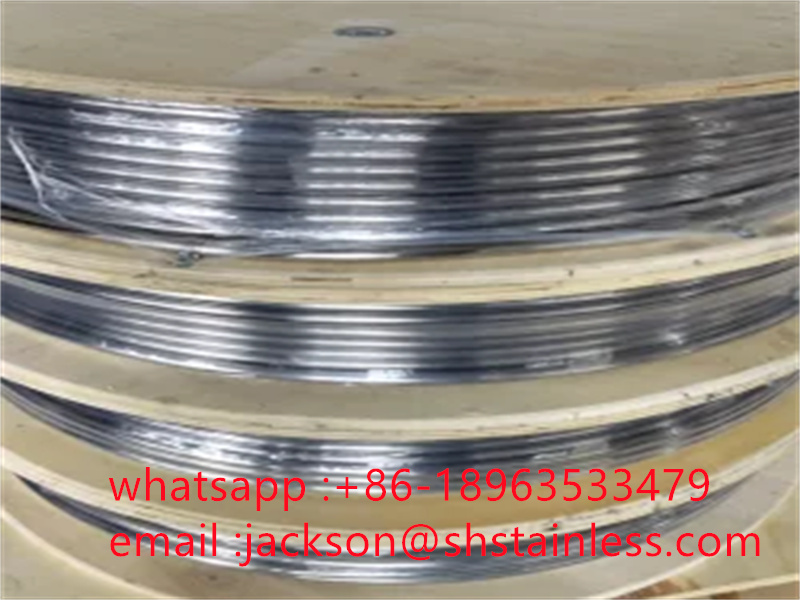

DIN 1.4438 EFW Tube Available According To International Standards And Specifications Stainless steel capillary coiled tubingAs with alloy 316, the chemistry of low carbon stainless steel contains chromium, nickel, and molybdenum. An austenitic alloy belonging to the 300 series, the 317L Stainless Steel Seamless Tubes are considered to be a modification over grade 316. The content of molybdenum in this alloy’s chemistry is higher than 3%. This modified molybdenum grade alloy has several important characteristics. For instance, the WERKSTOFF NR.1.4438 Heat exchanger Tube demonstrates greater resistance to pitting and crevice corrosion compared to alloy 316.

STAINLESS STEEL COIL TUBE SPECIFICATION

| Stainless Steel Seamless Coil Tubing Specifications | ASTM A213 (average wall) and ASTM A269 |

| Outside Diameter | 1/16” through 3/4" |

| Stainless Steel Welded Coil Tubing Specifications | ASTM A249 and ASTM A269 |

| Grades | TP - 304,304L,316,316L,201, 2205, 2507 |

| Thickness | . 010" through .083” |

Stainless Steel Coil Tube (WELDED 304/L OR 316/L)

| Outside Diameter (OD) | Wall Thickness |

| 1/8” – 3/4” | 0.5mm – 4mm |

Stainless Steel Coil Tube(SEAMLESS 316/L)

| Outside Diameter (OD) | Wall Thickness | |

| 1/16” – 3/4” | 0.5mm – 4mm | |

STAINLESS STEEL COIL TUBE CHEMICAL COMPOSITION

The below table shows the chemical composition of the used for Stainless Steel Coil Tube:| GRADES | UNS | C | Mn | P | S | Si | Cr | Ni | Mo | Ti | Nb | N |

| TP304 | S30400 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-11.0 | ||||

| TP304L | S30403 | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-13.0 | ||||

| TP316 | S3160 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 | |||

| TP316L | S31603 | 0.035 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

SS COIL TUBE MECHANICAL PROPERTIES

| Material | Heat | Temperature | Tensile Strength | Yield Strength | Elongation %, Min |

| Treatment | Min. | Ksi (MPa), Min. | Ksi (MPa), Min. | ||

| º F(º C) | |||||

| TP304 | Solution | 1900 (1040) | 75(515) | 30(205) | 35 |

| TP304L | Solution | 1900 (1040) | 70(485) | 25(170) | 35 |

| TP316 | Solution | 1900(1040) | 75(515) | 30(205) | 35 |

| TP316L | Solution | 1900(1040) | 70(485) | 25(170) | 35 |