Specifications

| Specification | Thickness | 1-5mm |

| Width | 10-200mm | |

| Length | 5.8-6 Meters | |

| Standard | ASTM A53/ASTM A573/ASTM A283/ | |

| GB/T9711.1-1997 | ||

| DIN1629/4 DIN1629/3 | ||

| Material | Q195,Q215,Q235B,Q345B,S235JR/S355JR/SS400 | |

| Finished | Black/Galvanized/Coated/Oiled/Painting,etc. | |

| Usage | Construction, machinery manufacturing, steel construction projects, solar power support | |

| Steel structure engineering, power engineering, power plants, agricultural and chemical machinery, glass curtain walls, automobile chassis, airports, etc. | ||

| Technique | ERW Welded | |

| Packing | Standard sea worthy packing, tied by steel strip | |

| Or pack as customized requirement | ||

| Country of Original | China | |

| Main Market | Middle East,Africa,Asia,South America,Eastern Europe | |

| MOQ | 5 Tons | |

| Productivity | 500 Tons/Month | |

| Trade & Payment | Trade: | EXW,FOB,CFR,CIF,DDP |

| Payment: | ≤ $8,000 T/T 100% advance | |

| > $8,000 T/T(30%+70%),30%T/T + 70%L/C | ||

| Further Service | Drilling/Punching | |

| Customized cutting size | ||

| Customized surface process | ||

| Bending/Welding/Decoiling | ||

| TYPE | APPLICATION |

| Steel Plate | Various abrasive handles and other unimportant abrasive parts, Ship building |

| Steel Coil | Widely used in the manufacture of general mechanical parts. Mainly used for welding structural parts with high quality requirements in construction and bridge engineering. |

| Steel Strip | Manufacturing process, same as steel coil |

| Steel Pipe | Construction, machinery manufacturing, steel construction projects, shipbuilding, solar power support, steel structure engineering, power engineering, power plants, agricultural and chemical machinery, glass curtain walls, automobile chassis, airports, etc. |

| Steel Bar | Used to make cutting tools, molds and measuring tools |

| Material | ASTM A269 Chemical Composition % Max | ||||||||||

| C | Mn | P | S | Si | Cr | Ni | Mo | N B | Nb | Ti | |

| TP304 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 18.0-20.0 | 8.0-11.0 | ^ | ^ | ^ . | ^ |

| TP304L | 0.035 | 2.00 | 0.045 | 0.030 | 1.00 | 18.0-20.0 | 8.0-12.0 | ^ | ^ | ^ | ^ |

| TP316 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 | ^ | ^ | ^ |

| TP316L | 0.035 D | 2.00 | 0.045 | 0.030 | 1.00 | 16.0-18.0 | 10.0-15.0 | 2.00-3.00 | ^ | ^ | ^ |

| TP321 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 17.0-19.0 | 9.0-12.0 | ^ | ^ | ^ | 5C -0.70 |

| TP347 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 17.0-19.0 | 9.0-12.0 | 10C -1.10 | ^ | ||

| Material | Heat treatment | Temperure F (C) Min. | Hardness | |

| Brinell | Rockwell | |||

| TP304 | Solution | 1900 (1040) | 192HBW/200HV | 90HRB |

| TP304L | Solution | 1900 (1040) | 192HBW/200HV | 90HRB |

| TP316 | Solution | 1900(1040) | 192HBW/200HV | 90HRB |

| TP316L | Solution | 1900(1040) | 192HBW/200HV | 90HRB |

| TP321 | Solution | 1900(1040) F | 192HBW/200HV | 90HRB |

| TP347 | Solution | 1900(1040) | 192HBW/200HV | 90HRB |

| OD, inch | OD Tolerance inch(mm) | WT Tolerance % | Length Tolernace inch(mm) | |

| + | - | |||

| ≤ 1 / 2 | ± 0.005 ( 0.13 ) | ± 15 | 1 / 8 ( 3.2 ) | 0 |

| > 1 / 2 ~1 1 / 2 | ± 0.005(0.13) | ± 10 | 1 / 8 (3.2) | 0 |

| > 1 1 / 2 ~< 3 1 / 2 | ± 0.010(0.25) | ± 10 | 3 / 16 (4.8) | 0 |

| > 3 1 / 2 ~< 5 1 / 2 | ± 0.015(0.38) | ± 10 | 3 / 16 (4.8) | 0 |

| > 5 1 / 2 ~< 8 | ± 0.030(0.76) | ± 10 | 3 / 16 (4.8) | 0 |

| 8~< 12 | ± 0.040(1.01) | ± 10 | 3 / 16 (4.8) | 0 |

| 12~< 14 | ± 0.050(1.26) | ± 10 | 3 / 16 (4.8) | 0 |

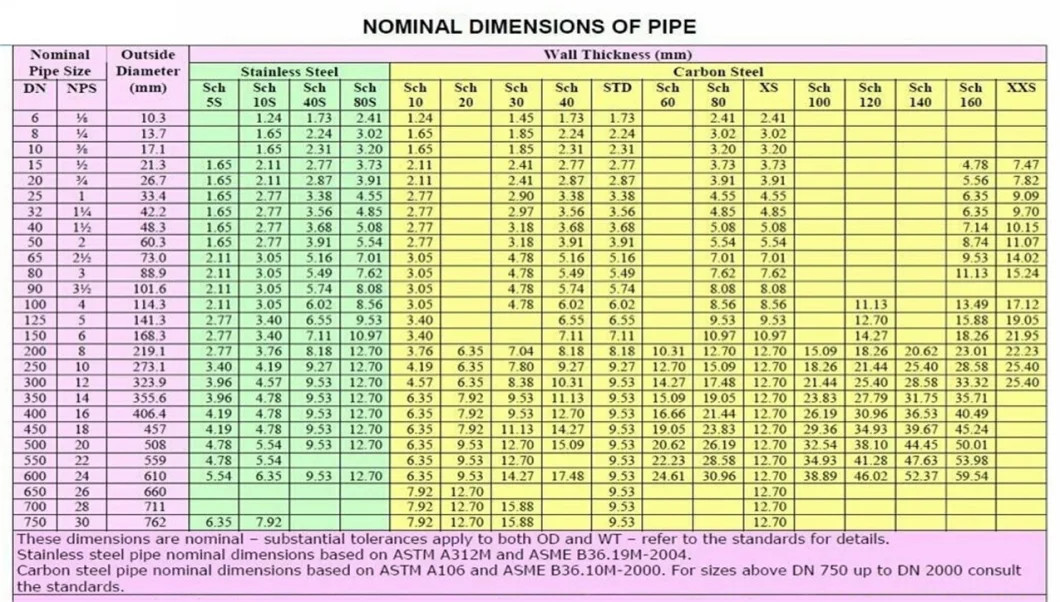

Nominal Dimensions Of Pipe

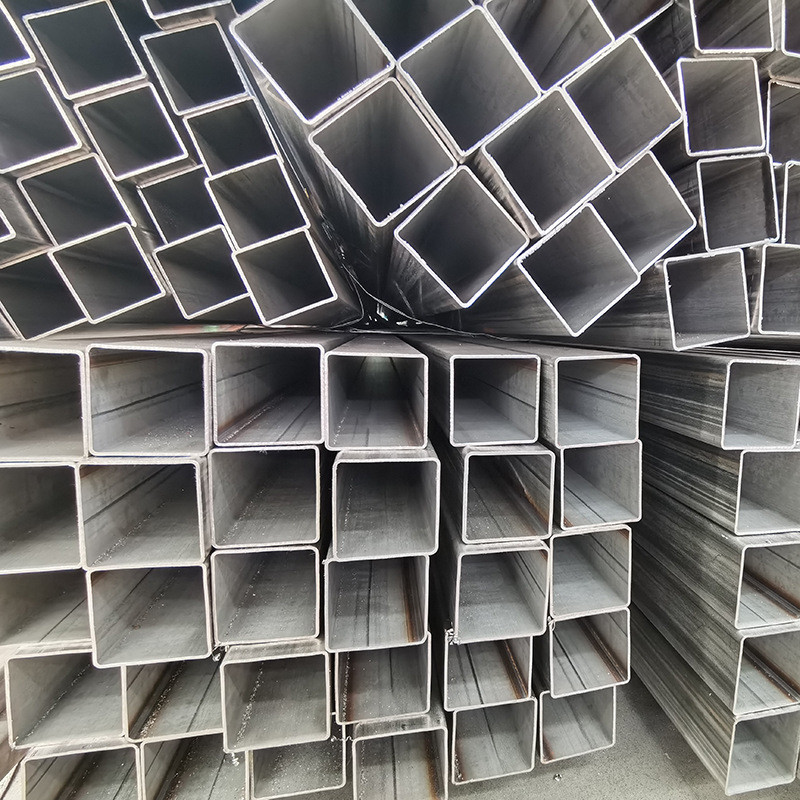

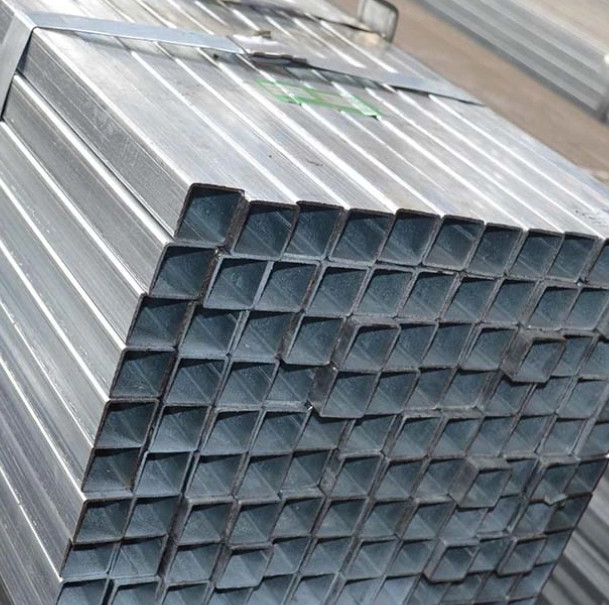

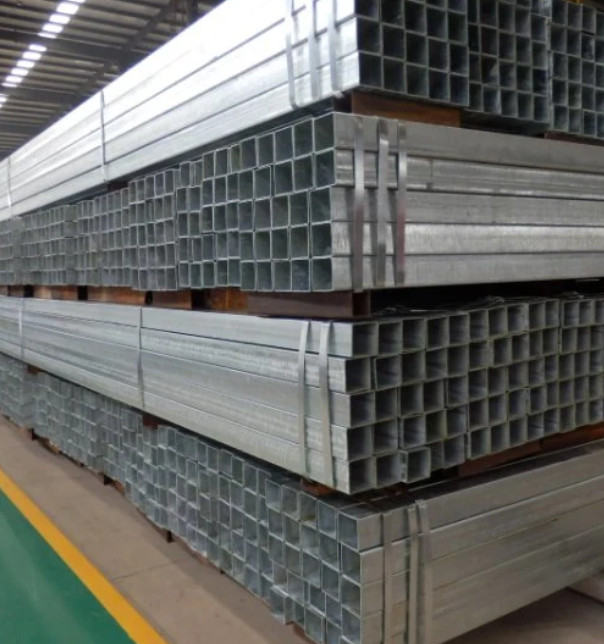

Factoy photos